Carbon commutator

Carbon commutator

- 1. Life cycle increase 70%

- 2. Better resistance of E15 and E85

- 3. Power increasing approx 10%

Fix once to do machining all dimensions

Fix once to do machining all dimensions

- 1. Ensure concentricity ≤0.01mm

- 2. Reduce vibration

Scoop type impeller

Scoop type impeller

- 1. Low noise, decrease from 45dB to 42dB

- 2. Improve fuel supply efficiency.

Product features

1. Pressure sensors are purchased from same chip OE supplier;

2. Reduce extremely low minimum fuel working level from 20mm to 10mm;

3. All plastic parts are produced with imported high-performance POM raw materials;

4. Module use the fuel pump with most mature structure (38 series), which can resist ethanol, and with higher efficiency and longer service life.

2. Reduce extremely low minimum fuel working level from 20mm to 10mm;

3. All plastic parts are produced with imported high-performance POM raw materials;

4. Module use the fuel pump with most mature structure (38 series), which can resist ethanol, and with higher efficiency and longer service life.

Pressure sensor

Pressure sensor Ceramic sender card

Ceramic sender card

- Ensuring accurate fuel reading

High-density dual layer strainer

High-density dual layer strainer

- Designed for better contamination resistance

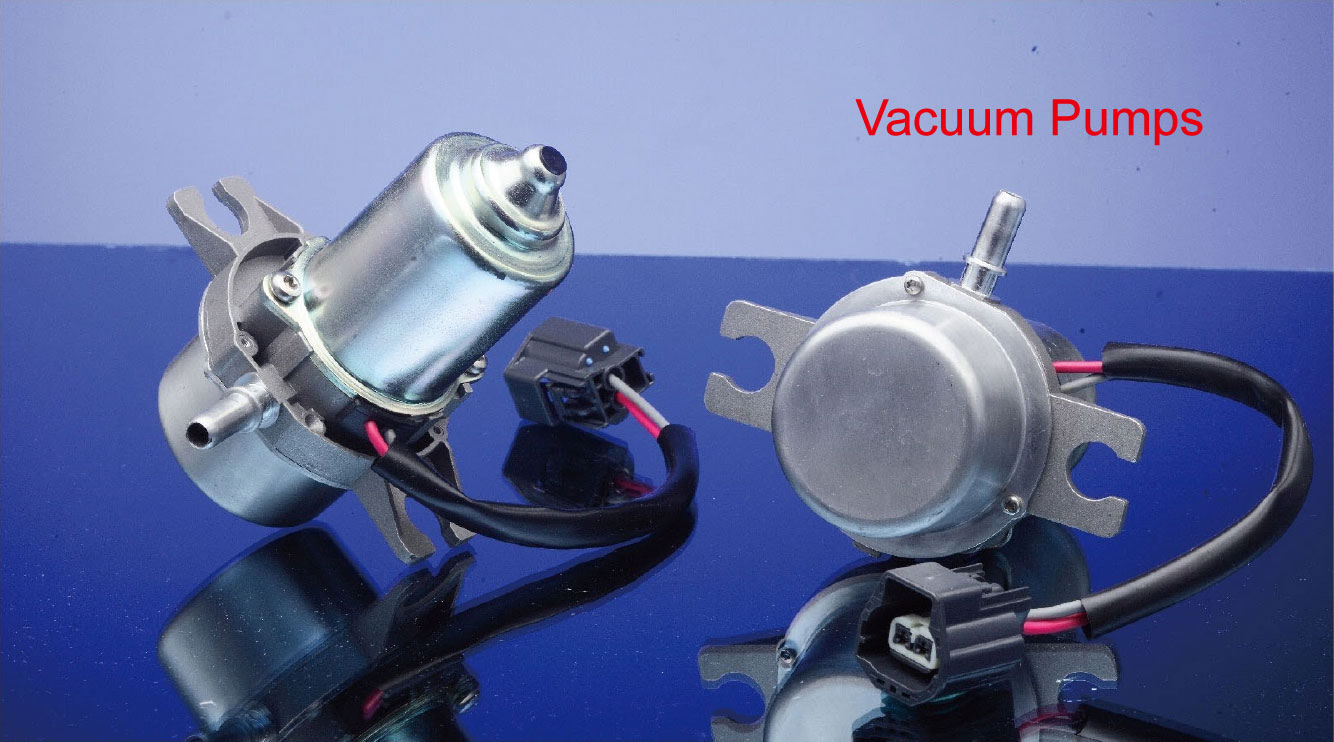

- Definition

- Until recently the majority of brake boosters used the vacuum generated by the internal combustion engine's intake section. With new engine technologies (e.g. hybrid vehicles, downsizing) or in specific operating conditions (e.g. during the cold start/warm-up phase, driving at extreme altitudes or when using the air-conditioning system), the vacuum produced by the engine is no longer sufficient Electric vacuum pumps are used to ensure the reliable operation of the brake booster. Aside from the internal combustion engine, modem engine technologies such as those found in electric or hybrid vehicles are not able to build up vacuum pressure.

The electric vacuum pump is therefore required to generate an alternative or additional vacuum for these technologies.

This additional vacuum pump ensures compliance with the latest safety standards, while reliable running of the braking system, which operates with pneumatic brake boosters, is maintained

- Until recently the majority of brake boosters used the vacuum generated by the internal combustion engine's intake section. With new engine technologies (e.g. hybrid vehicles, downsizing) or in specific operating conditions (e.g. during the cold start/warm-up phase, driving at extreme altitudes or when using the air-conditioning system), the vacuum produced by the engine is no longer sufficient Electric vacuum pumps are used to ensure the reliable operation of the brake booster. Aside from the internal combustion engine, modem engine technologies such as those found in electric or hybrid vehicles are not able to build up vacuum pressure.

- Advantage

- 1. Improve driving comfort and safety.

- 2. Replacing mechanical pump to realize energy saving and emission reduction.

- 3. Reduction in energy requirements thanks to on-demand pump operation.

- 4. Helps to reduce C02 emissions.

- 5. Independent of combustion engine technology.

- 6. Maintenance-free (dry running and self-lubrication requires no connection to the oil circuit).

- 7. Electrically driven vacuum pumps support a flexible vehicle platform concept.

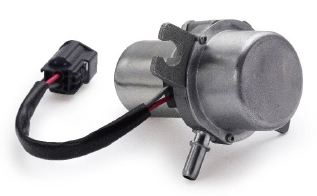

UP28

- Technique Data

UP28 Vacuum Pumps Operating temperature -40°C-+100°C

(< 20 min. at up to +120°C)Maximum vacuum level 86%(under ambient pressure) Pressure build-up time

(with 13V and 4 I test volume)50% of ambient pressure: ts 6.2 s

70% of ambient pressure: ≤11.7s- The UP28 vacuum pump is activated on demand to support the evacuation of the brake booster. The UP28 can provide the necessary vacuum for the brake booster in a wide range of situations when the internal combustion engine is unable to do so, e.g. during the cold start/warm-up phase, at high altitudes or when using the air-conditioning system. The UP28 is installed parallel to the main combustion engine and evacuates filtered air via the brake booster and flexible pneumatic hoses.

UP30/32

- Technique Data

UP30/32 Vacuum Pumps Operating temperature -40°C-+100°C Maximum vacuum level 86%(under ambient pressure) Pressure build-up time

(with 13V and 4 I test volume)50% of ambient pressure: t s 3.3 s/2.4 s

70% of ambient pressure: U 6.2 s/4.4 s- The cost savings and energy advantages of conventional brake systems equipped with a pneumatic brake booster can also be applied to advanced vehicle technologies such as future downsized engines and hybrid/fuel cell vehicles by incorporating a vacuum pump. These pumps are able to supply the necessary vacuum independent of the engine technology. The UP30/32 supplies a vacuum to the brake booster, and when required, to the engine compartment actuators. The UP30/UP32 is installed in the pneumatic section of the brake system, just like the UP28. Both vacuum pumps are ideal for vehicles without any vacuum, such as hybrid/fuel cell, electric or diesel engines.